How does 3D printing work?

3D printing is a process of creating three-dimensional objects through the layer-by-layer addition of materials, a technique known as additive manufacturing. Here’s a step-by-step overview of how 3D printing works:

Design

The process begins with creating a three-dimensional model using computer-aided design (CAD) software or by converting data from 3D scans into a digital format. This model is then exported as an STL or OBJ file, which is readable by 3D print preparation software124.

Slicing and Preparation

The 3D model is then sliced into horizontal cross-sections by slicing software. This software generates instructions, known as G-code, which tell the 3D printer how to move and deposit material layer by layer. The software also allows for the adjustment of print settings such as orientation, support structures, layer height, and material selection123.

Printing

The actual printing process varies depending on the type of 3D printing technology used:

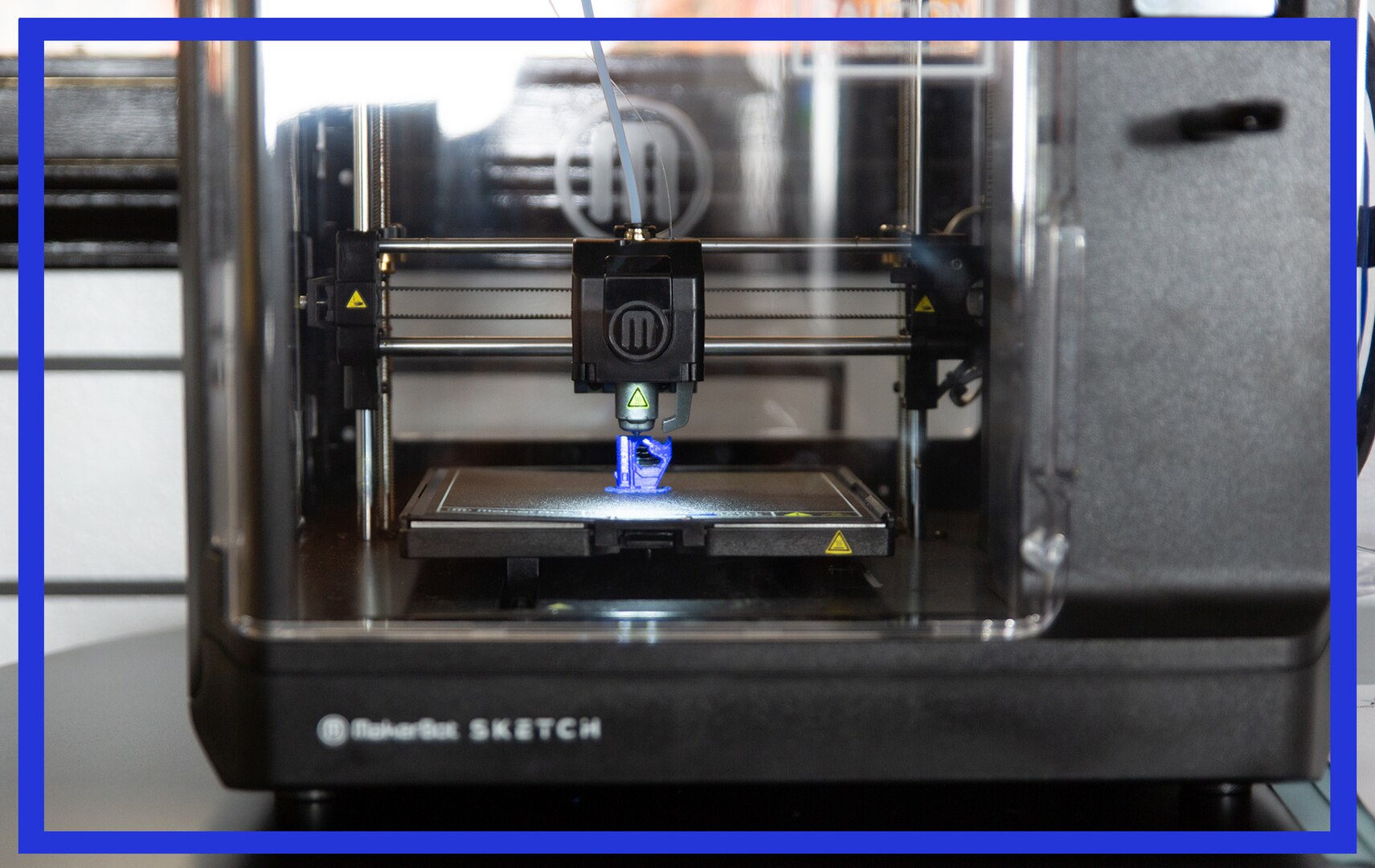

Fused Deposition Modeling (FDM)

FDM, the most common consumer-level 3D printing technology, works by extruding thermoplastic filaments (like PLA or ABS) through a heated nozzle. The melted filament is deposited layer by layer onto a build platform, where it solidifies to form the object123.

Stereolithography (SLA) and Digital Light Synthesis (DLS)

These technologies use resin that is solidified by UV light. In SLA, a laser solidifies the resin layer by layer, while DLS uses a projector to solidify the resin in a single layer, followed by a thermal bath to complete the curing process12.

Powder Bed Fusion (PBF)

Technologies like Selective Laser Sintering (SLS) use a high-power laser to fuse small particles of powder together, layer by layer, to create the object2.

Binder Jetting and Material Jetting

Binder Jetting involves layering powder and applying a liquid binder to fuse the powder particles together. Material Jetting uses droplets of material that are hardened by UV light2.

Post-Processing

After the printing is complete, the parts may require additional processing. This can include:

- Rinsing with isopropyl alcohol to remove uncured resin.

- Post-curing to stabilize mechanical properties.

- Removing support structures.

- Cleaning with compressed air or a media blaster to remove excess powder.

- Further processing such as machining, priming, painting, or joining to achieve the desired finish12.

Key Components and Mechanisms

- Toolhead and Build Plate: The toolhead moves in three dimensions (X, Y, Z axes) to deposit material, while the build plate moves to accommodate each new layer3.

- Stepper Motors: These motors control the precise movement of the toolhead and build plate.

- Support Structures: For objects with overhanging parts, support structures are often necessary to ensure proper printing3.

In summary, 3D printing involves designing a 3D model, slicing it into layers, printing those layers using various technologies, and then post-processing the printed part to achieve the desired properties and finish.